Handcrafted Cards

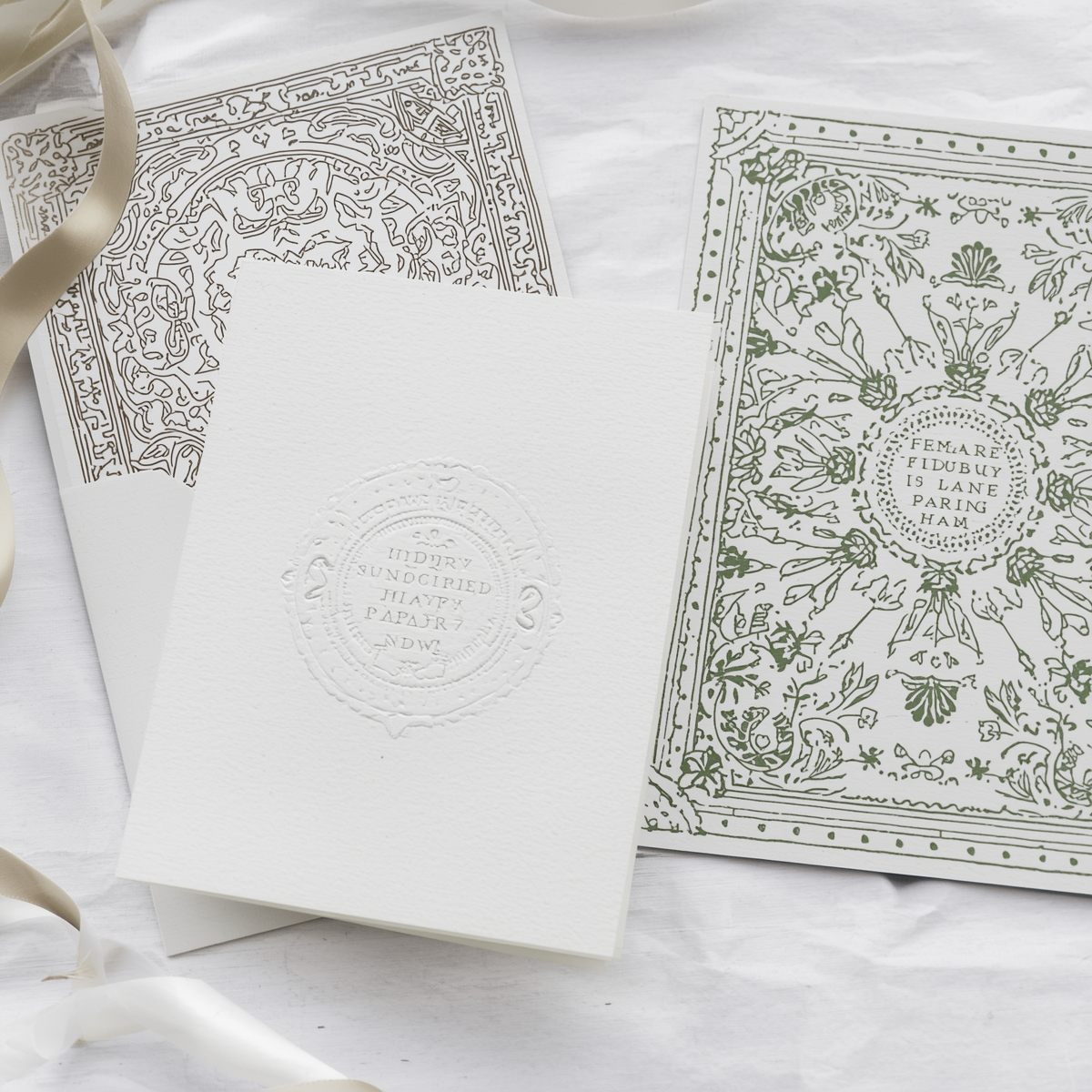

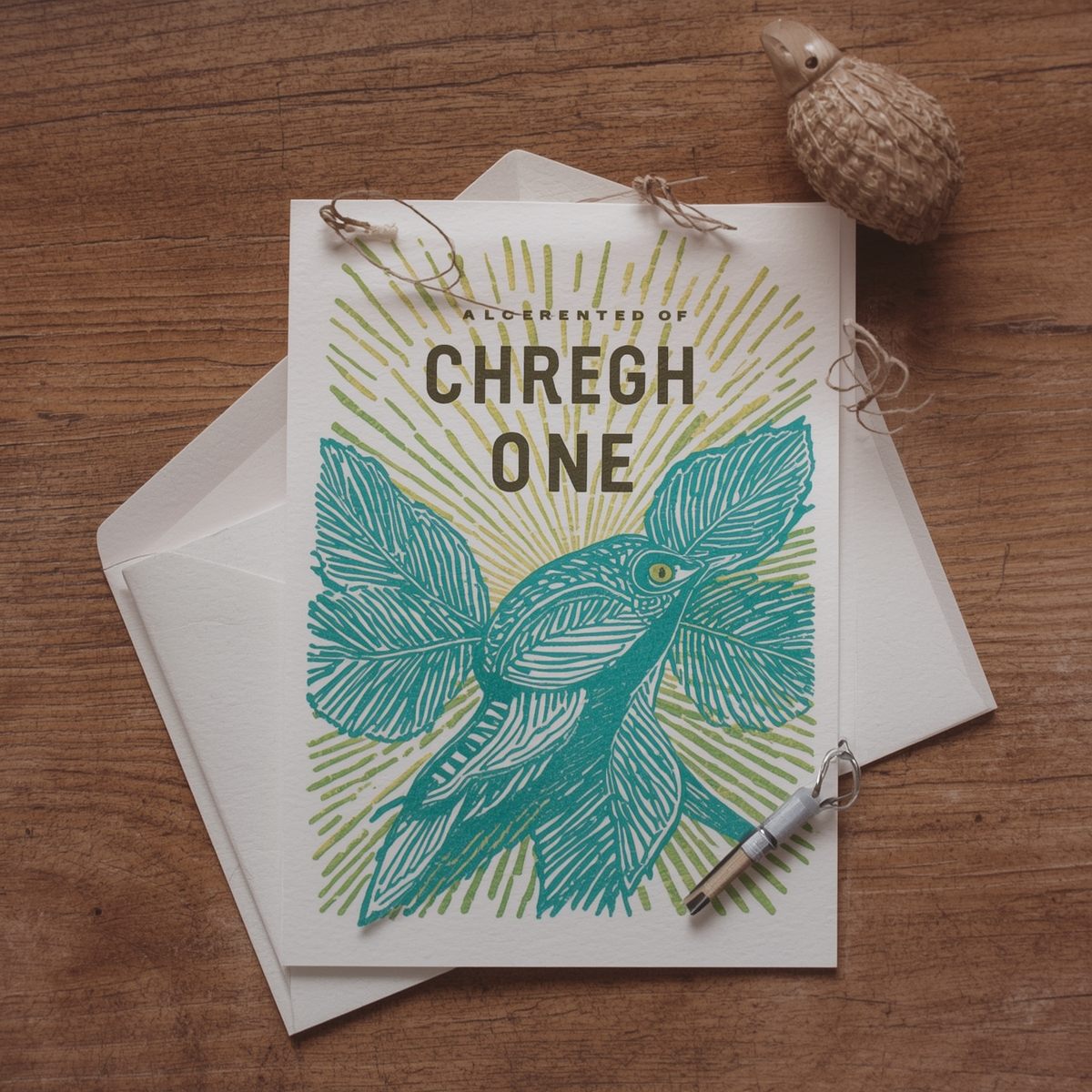

Our greeting cards begin with a design conceived specifically for letterpress printing. The process honors the limitations and advantages of the medium: the way ink sits on paper, how embossing creates dimension, the relationship between negative space and printed elements.

Each design is first created on paper or digitally, then translated into physical plates or type. Custom plates are made from polymer or metal, depending on the complexity and requirements of the design. We hand-set type when appropriate, selecting from our collection of metal and wood typefaces.

The printing process is deliberate. Paper is selected for weight, texture, and how it accepts ink. Colors are mixed to achieve exact specifications. Registration must be precise, especially when combining multiple colors or adding embossing.

Design Development

Card designs evolve through a careful process of refinement. Initial concepts are tested through proofs, allowing us to see how designs translate from screen or sketch to printed form.

The letterpress process affects design decisions: fine details may be lost, certain colors may not achieve desired opacity, and embossing requires sufficient space and contrast to be effective.

The Embossing Process

Embossing adds a tactile dimension that cannot be achieved through printing alone. Custom dies are created for each design, cut with precision to match the artwork. The embossing process occurs either inline with printing or as a separate step.

When paper is pressed between the die and counter-die, fibers are compressed, creating a raised or recessed surface. The result is visible in certain light and tangible to touch. This quality distinguishes handcrafted cards from mass-produced alternatives.

Finishing and Presentation

After printing and embossing, cards are inspected individually. Each piece must meet our standards for registration, ink coverage, and overall quality. Cards that do not meet these standards are set aside.

We package cards simply, allowing the quality of the piece to be the focus. They are suitable for immediate use or storage. The heavy card stock and careful production ensure they maintain their appearance over time.

Quality Assurance

Every card undergoes individual inspection. We check for registration accuracy, ink coverage consistency, embossing quality, and overall finish. Only cards that meet our standards proceed to packaging and distribution.

Color Palette

We work with limited color palettes that complement the letterpress process. Single-color designs with embossing are common, as are two-color combinations that take advantage of registration possibilities.

Ink colors are custom-mixed to achieve specific tones that cannot be achieved with standard inks. This attention to color detail contributes to the distinctive appearance of our cards.

Our card designs are available in limited quantities. For custom designs or specific requirements, we work directly with clients to develop pieces that meet their needs.

Inquire About Cards