Techniques & Materials

This documentation outlines the methods and materials we use in our work. Understanding the process helps explain the qualities of the finished pieces.

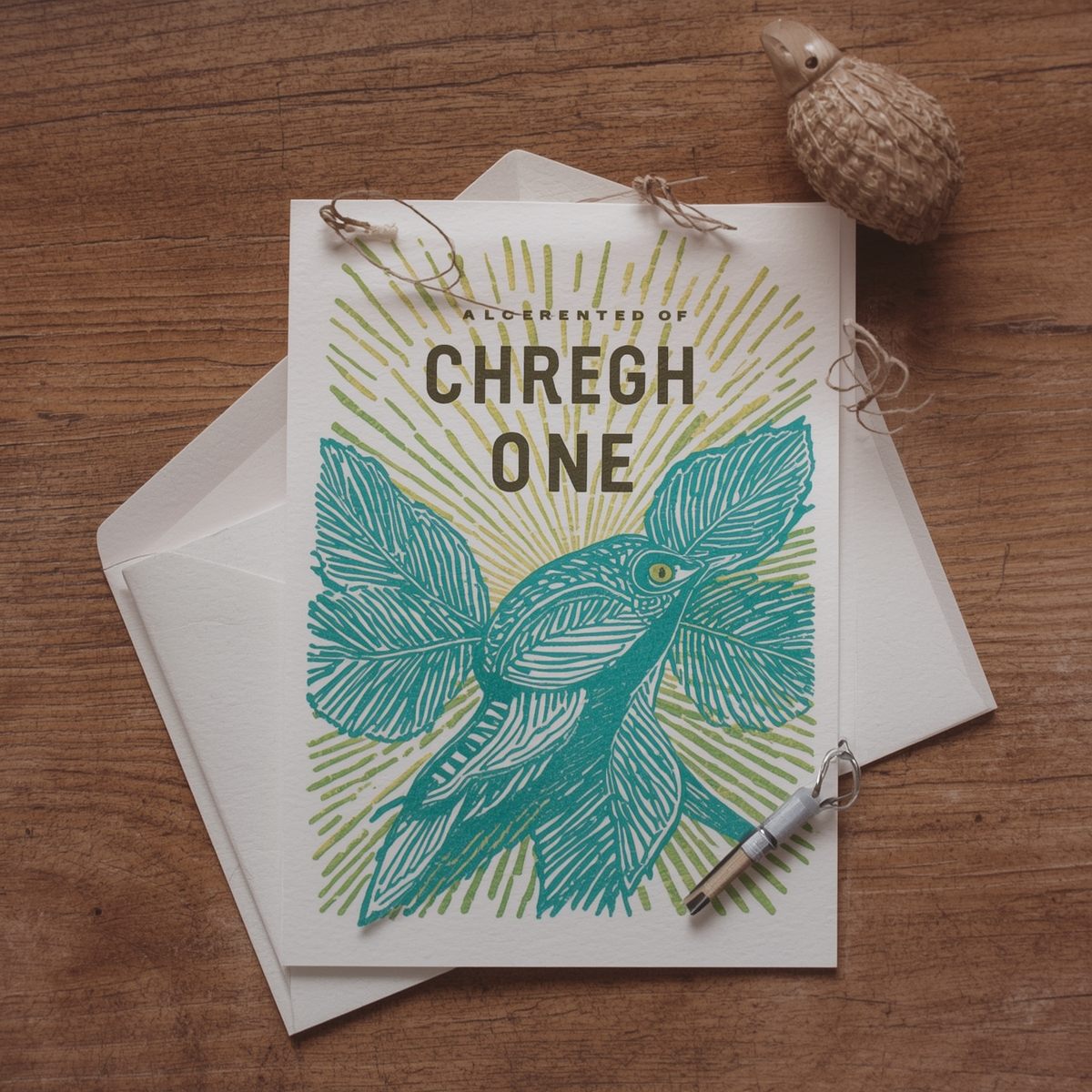

Letterpress Printing

Letterpress printing uses raised surfaces to apply ink to paper. Type, plates, or custom-made elements are locked into a chase and mounted on a press. Ink is applied to the raised surfaces using rollers, then paper is pressed against the inked elements.

The printing process requires precise registration and consistent pressure to achieve uniform ink coverage.

We maintain several letterpress machines, ranging from platen presses suitable for cards and stationery to larger cylinder presses for folios and larger format work. Each machine requires regular maintenance and adjustment to operate correctly.

Modern letterpress printing often uses polymer plates made from digital designs, though we also work with metal type and custom-cut plates depending on the project requirements.

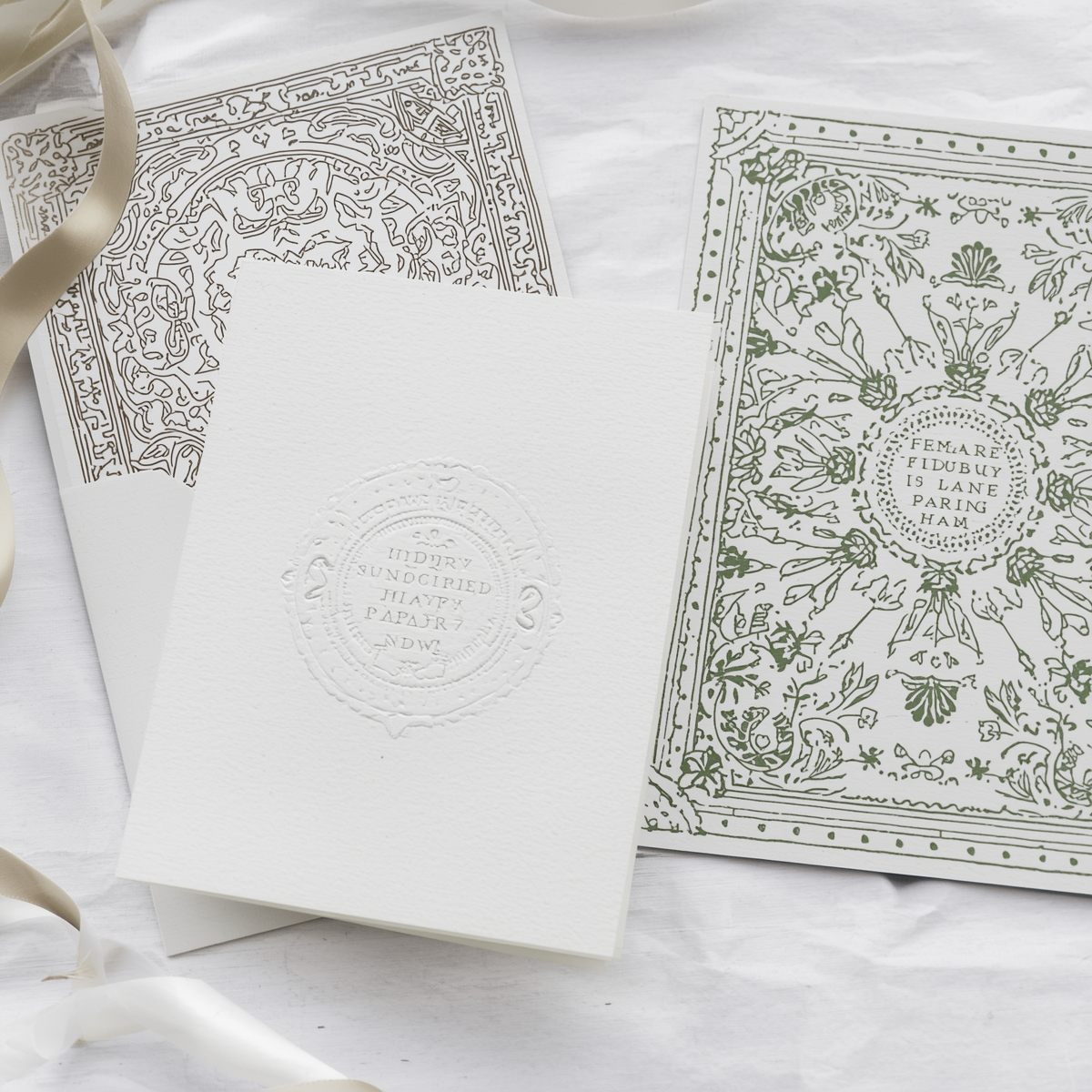

Embossing and Debossing

Embossing creates raised surfaces in paper, while debossing creates recessed surfaces. Both processes use custom-made dies that compress paper fibers when pressed between the die and counter-die.

Dies are precision-cut to match the artwork and must align perfectly with counter-dies to create clean impressions.

The embossing process can be combined with printing or performed as a separate step. When combined, registration between printed elements and embossed surfaces must be carefully maintained.

We create dies using various methods, including hand-cutting, laser-cutting, and traditional die-making techniques. The choice depends on the complexity of the design and the required precision.

Ink and Color Mixing

We mix custom ink colors to achieve specific results. The process begins with base colors and additives, measured precisely to create consistent batches.

Custom colors allow us to match specific requirements and create unique palettes for individual projects.

Ink formulation considers the paper stock, the printing method, and the desired appearance. Some papers absorb ink differently, requiring adjustments to achieve consistent results.

We document color formulas for projects that require reprints or larger production runs, ensuring consistency across batches.

Paper Selection

Paper choice significantly affects the appearance and feel of printed pieces. We work with various stocks, including cotton, linen, and specialty papers, each selected for specific characteristics.

Texture, weight, and how paper accepts ink and embossing are primary considerations in selection.

Cotton papers offer smooth surfaces and excellent ink holdout. Linen papers provide distinctive textures and visual interest. Specialty stocks may include recycled content, unusual textures, or specific weight requirements.

We test paper samples before committing to large production runs, evaluating how each stock responds to our printing and embossing processes.

Type and Typography

We maintain a collection of metal and wood type, suitable for hand-setting text. When appropriate, we set type manually, selecting from available fonts and sizes.

Hand-set type requires knowledge of spacing, leading, and proper locking in the chase for printing.

Digital designs are translated into polymer or metal plates when hand-setting is not practical or when specific typefaces are required. The goal is to maintain the quality and character of letterpress printing regardless of the source material.

Typography choices consider readability, aesthetic goals, and the technical limitations of letterpress printing, particularly regarding fine details and small sizes.

Press Maintenance

Regular maintenance is essential for consistent printing quality. We service our presses according to manufacturer specifications and our experience with their operation.

Maintenance includes cleaning, lubrication, adjustment of pressure settings, and replacement of worn parts. Some repairs require custom fabrication or sourcing of vintage components.

Well-maintained equipment ensures consistent results and extends the working life of our presses, many of which have been in operation for decades.

Quality Control

Throughout the production process, we monitor print quality continuously. Each sheet is inspected as it comes off the press, checking for registration accuracy, ink coverage, and overall appearance.

Adjustments are made immediately when issues are detected. This real-time quality control prevents wasted materials and ensures that production runs meet our standards from start to finish.